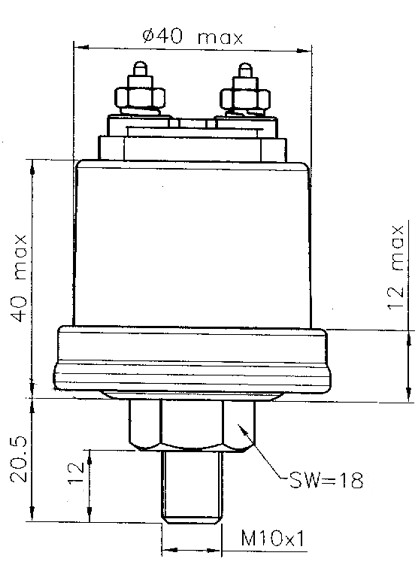

M10X1.0 10Bar Mechanical Oil Pressure Sensor Transducer Pressure Switch With Alarm

| Model Number | CDYG3-03041400 |

| Measuring range | 0~10bar(0-5bar are avilable) |

| Output resistance | 10-184Ω (9~180Ω are avilalble) |

| Alarm | 1.4bar (0.8bar are avilable) |

| Operating temperature | -40 ~125℃ |

| Operating voltage | 6~24VDC |

| Conduction power | <5W |

| Output Connection | G- instrument, WK- alarm |

| Screw torgue | 1N.m |

| Install torgue | 30N.m |

| Thread fitting | M10X1.0( customized as requires Parameters ) |

| Material | Metal (color znic plated / Blue and white znic plated) |

| Protection rank | IP66 |

| Laber | Laser marking |

| Minimum Order Quantity | 50pcs |

| Delivery Time | within 2-25working days |

| Packaging Details | 25pcs /foam box , 100pcs / out carton |

| Supply Ability | 200000pcs/Year. |

| Place of Origin | Wuhan,China |

| Brand Name | WHCD |

This pressure range of the sensor is 0-10Bar, the corresponding resistance value is the conventional 10-184Ω, Thread fitting: M10X1.0;the Alarm point is 1.4Bar;

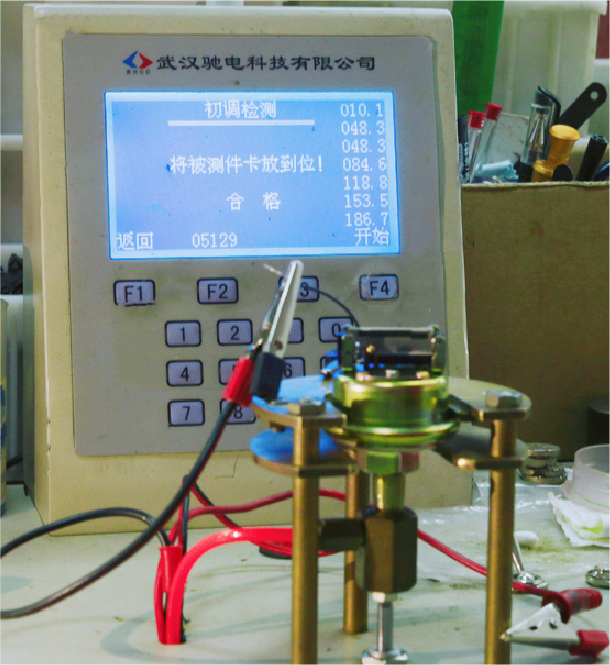

This sensor has strictly passed the Automotive Industry: QC/T822-2009 all standard requirements, Testing items include: Error accuracy, Overload pressure, High and low temperature test, Waterproof, Anticorrosive, Shockproof, Collision resistance, Durability test and so on, can work in harsh environment and Bad weather for a long time.It can keep monitoring the working state of engine in real time accurately.

Our pressure switches are accurate, in use to ensure accurate system pressure while alerting the operator when problems occur.

Especially those involving heavy industry engines as well as hydraulic and pneumatic industrial systems require stable pressure to operate efficiently and correctly.

If the pressure displayed on the instrument is too high, the pressure range of the appropriate pressure sensor may be inappropriate.

Therefore, it is necessary to replace the pressure sensor in time. If the pressure is too low, the device may fail or the pressure pipeline may leak.

Pressure switches typically provide a discrete output signal triggered by a simple set point, while pressure transmitters provide absolute, gauge or differential analog readings over a wide range of measurements.

It combines the advantages of excellent anti-vibrat ion performance, long service life, simple assembly process, stable quality, wide range of operating temperature, etc.