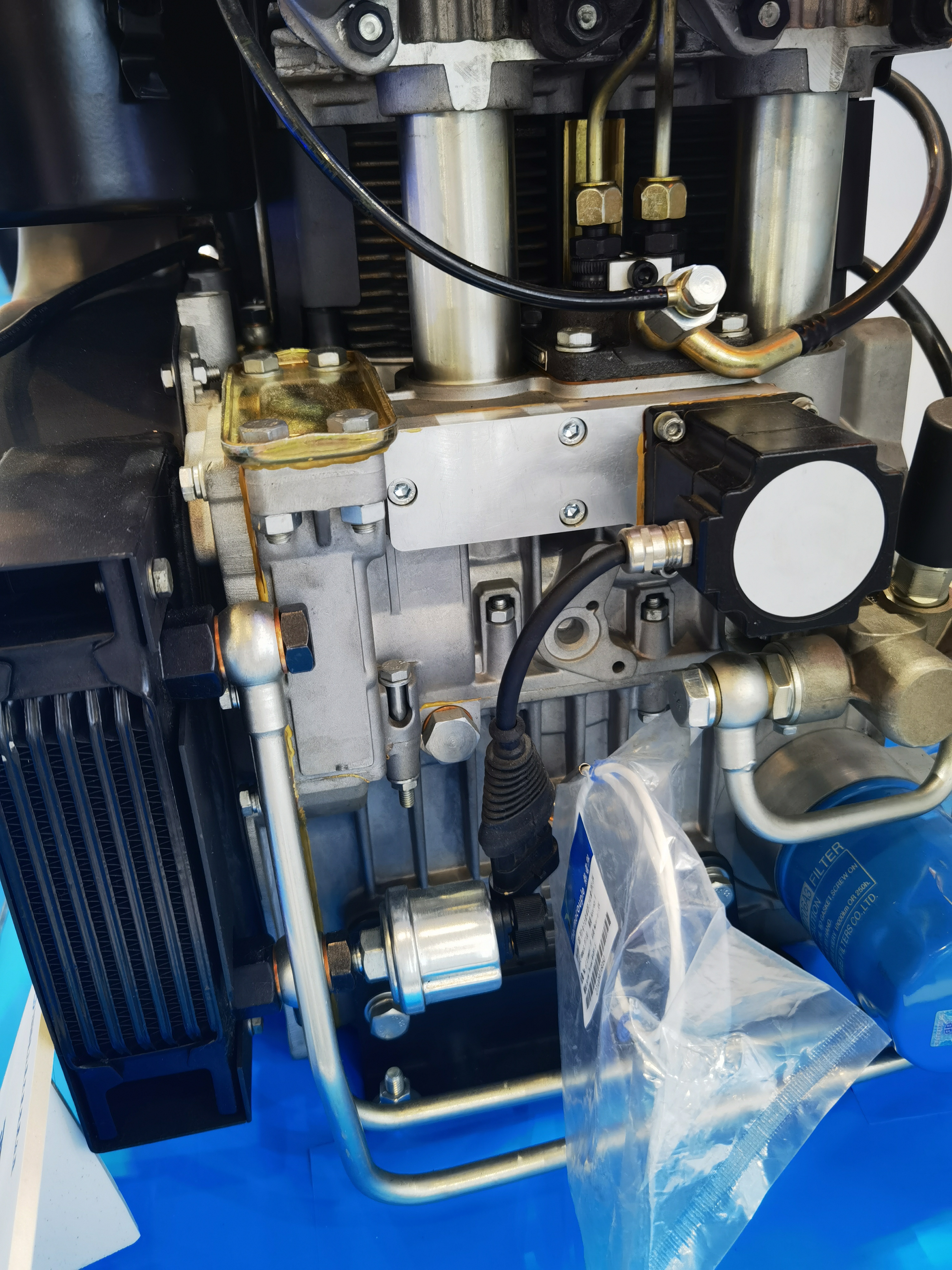

The oil pressure sensor is installed in the main oil channel of the engine. When the engine is running, the pressure measuring device detects the pressure of the oil, converts the pressure signal into an electrical signal and sends it to the signal processing circuit. After voltage amplification and current amplification, the amplified pressure signal is connected to the oil pressure indicator through the signal line, and the ratio of the current passed by the two coils inside the oil pressure indicator is changed. Thus indicating the engine oil pressure. The pressure signal after voltage amplification and current amplification is compared with the alarm voltage set in the alarm circuit. When it is lower than the alarm voltage, the alarm circuit outputs the alarm signal and lights the alarm lamp through the alarm line.

TElectronic oil pressure sensors are wired in exactly the same way as traditional mechanical sensors, It can replace the mechanical pressure transducer, directly connected with the automobile oil pressure indicator and low pressure alarm lamp, indicating the oil pressure of the diesel automobile engine and providing low pressure alarm signal. Compared with the traditional piezoresistive oil pressure sensor, the electronic automobile oil pressure sensor has the advantages of no mechanical moving parts (that is, no contact), high accuracy, high reliability, long life and so on, and meets the requirements of the development of automobile electronic.

Because the working environment of the car is very bad, the requirements of the sensor is very strict, in the design of the electronic automobile oil force sensor, not only need to choose high temperature resistance, corrosion resistance, high precision pressure measuring device, the selection of reliable performance, wide range of working temperature components, but also need to take anti-interference measures in the circuit, in order to improve the reliability of the sensor.

Post time: May-04-2023